Farmers plant corn in late April or May and harvest it with combines in the fall. After harvest, the corn is dried and stored on the farm or in grain elevators before being transported to mills and refineries. More on toronto.name.

Toronto’s grain elevators became a significant part of the city’s infrastructure, deeply intertwined with the development of Canada’s grain industry. At the turn of the 19th and 20th centuries, as Canada harnessed its agricultural resources, Toronto emerged as a key transportation hub for storing and exporting grains. The construction of the first elevators was driven by the need to improve the storage and transport of agricultural products. At the same time, their scale and architectural features became symbols of the city’s industrial strength.

How Does a Grain Elevator Work?

Combines harvest grain from fields and transfer it into grain carts or directly into trucks for transportation to grain elevators. These elevators are typically located near railways or waterways to facilitate grain transportation after processing. They are often situated in small rural areas to reduce the distance farmers need to travel. Grain elevators are often the tallest buildings in their vicinity, ranging from 70 to 120 feet in height.

Trucks delivering grain arrive at a local elevator and are weighed upon entry. Operators take samples to evaluate weight, moisture content, and the presence of foreign materials such as husks, stalks, weeds, or debris. Grain moisture must be around 15% for storage—higher moisture levels risk mould, while lower levels risk overdrying. If the grain is too moist, farmers pay to have it dried at the elevator, which can reduce its market value per bushel.

Once evaluated, the grain is dumped onto the elevator’s work floor—a grated platform where it flows into a pit. From there, a continuous conveyor belt fitted with buckets scoops and transports the grain into silos. This bucket system moves grain from the floor to storage, giving the facility its name: a “grain elevator.” Once emptied, the truck returns to the scales to confirm the unloaded grain weight. The farmer receives a weight ticket with details like the date, quantity, grain type, and quality.

It is emptied from the truck onto the working floor of the grain elevator. This floor is an open, grated platform where the grain falls into a pit before moving along a continuous conveyor belt equipped with attached buckets that scoop it up. The grain is then stored in silos. This bucket system lifts the grain from the floor to the storage facility, which is why the entire installation is called a grain elevator. Once emptied, the truck returns to the scales to determine the weight of the unloaded grain. This information helps the elevator operator calculate the volume of corn delivered. The farmer then receives a receipt, known as a weight ticket, detailing the date, bushels delivered, grain type, and quality (the standard weight for a bushel is 56 pounds).

Grain elevators were designed to store harvested crops, including those purchased or held for resale. Their primary function is to protect grain from the elements and to monitor its quality and temperature. Inside, vertical storage bins allow for efficient transport and management of the grain. Proper storage is crucial: leaving crops in the field can reduce returns on investment due to pests, mould, birds, or rodents. Clean crops are essential, with moisture content being a key factor for safe storage. Excessive moisture can lead to mould and fungi, while as grain matures, moisture levels naturally decrease.

Storing grain also provides farmers with flexibility in marketing, enabling them to potentially secure better prices in a different season. However, storage comes with significant costs. As a result, farmers must carefully evaluate their storage capacity and anticipated profitability before deciding how much to store.

Early Development and Economic Significance

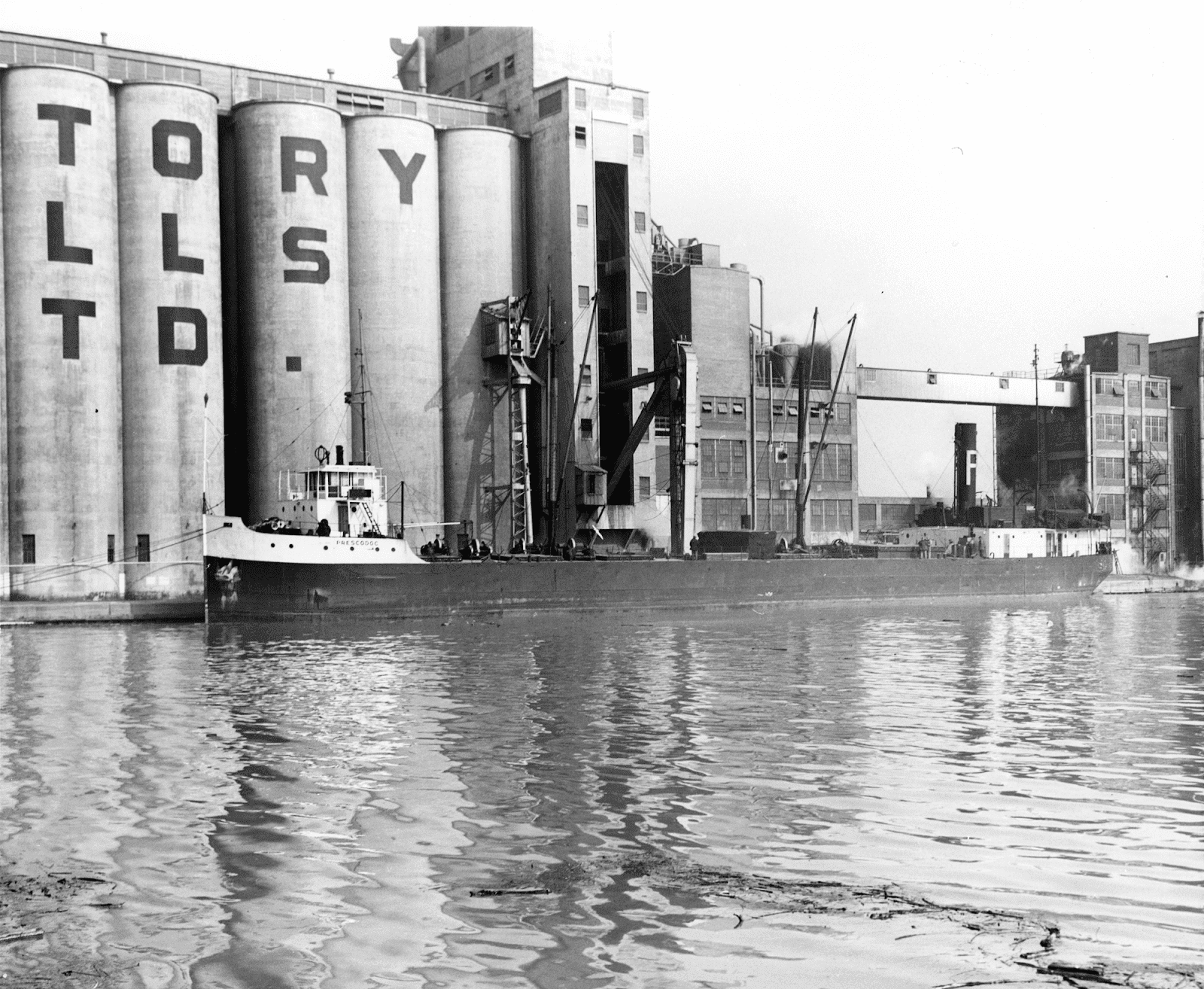

Grain elevators began appearing in Toronto in the late 19th century as Canada’s western prairies became a major grain supplier to Europe. With access to the Great Lakes and railway networks, Toronto played a vital role in transporting grain to ports for export. Early elevators were wooden structures, limited in reliability and safety. However, as reinforced concrete became prevalent in the early 20th century, elevators were replaced with more modern, massive structures. These new facilities were more durable and offered greater storage capacity. Large concrete silos, grain lifts, and intricate handling systems became defining features.

As grain export volumes grew, Toronto cemented its position in global trade. The city’s elevators not only stored grain but also sorted, processed, and prepared it for shipping via rail or ship. Reinforced concrete structures protected grain from weather and ensured optimal storage conditions. This advancement helped Canada’s grain industry gain international recognition and established Toronto as a significant hub of economic activity. Grain harvested on the western prairies passed through Toronto en route to European markets, contributing to Canada’s economic growth and creating jobs in various industries.

Challenges During the Great Depression

In the 1930s, Canada faced severe economic challenges during the Great Depression. The global economic downturn and declining demand for grain significantly impacted the grain industry and related sectors. To stabilize the situation, the government invested in modernizing elevators and other infrastructure. Building new elevators with automated systems optimized grain storage and transportation processes, providing employment opportunities during hard times.

The elevators constructed during this period were larger and more technologically advanced than their predecessors, becoming symbols of resilience and reliability. They played a crucial role in maintaining the nation’s economy and supporting its agricultural sector during a difficult era.

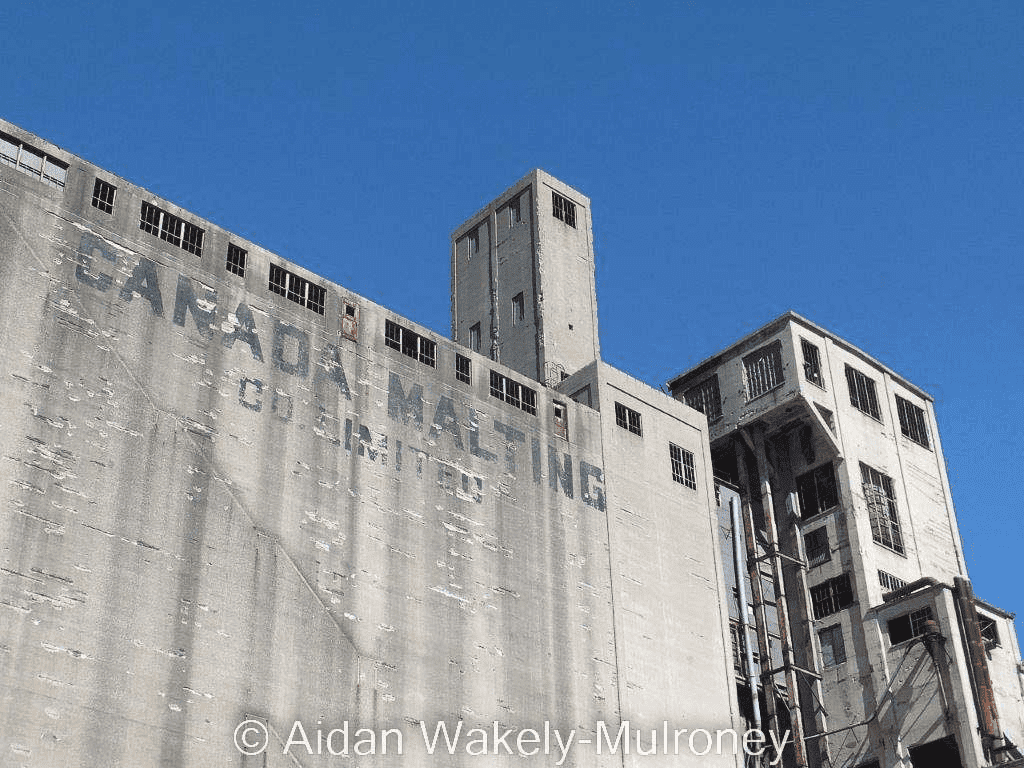

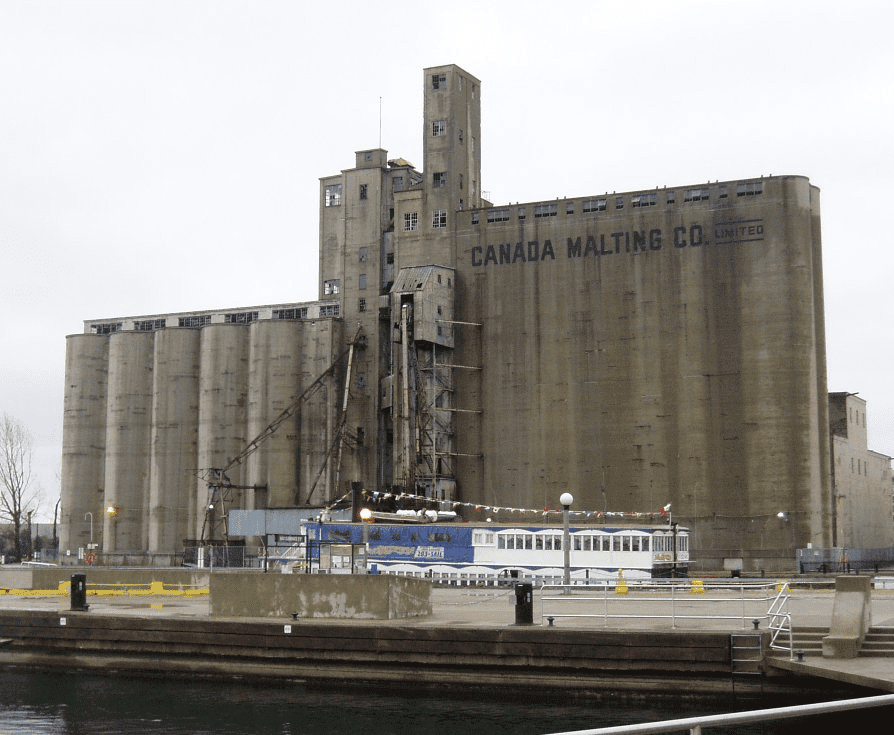

Architectural Significance and Current Status of Toronto’s Elevators

Toronto’s concrete grain elevators towered over industrial districts, symbolizing the power of the industrial era and serving as vital urban architectural elements. Often located near rail stations and ports, these elevators became visual markers of the city’s industrial development. Their tall silos, complex lifts, and cranes created a distinctive landscape characteristic of many Canadian cities.

As of 2024, most of Toronto’s historic elevators are no longer used for their original purposes. However, some have been preserved as important architectural landmarks, serving as reminders of the city’s industrial past. These elevators stand as witnesses to an era when grain was a cornerstone of international trade. Some have been repurposed into offices, warehouses, or cultural spaces, maintaining their place in the cityscape and highlighting Toronto’s history as a key industrial and transportation hub.

Sources: